“We can only see a short distance ahead, but we can see plenty there that needs to be done.”

Alan Turing

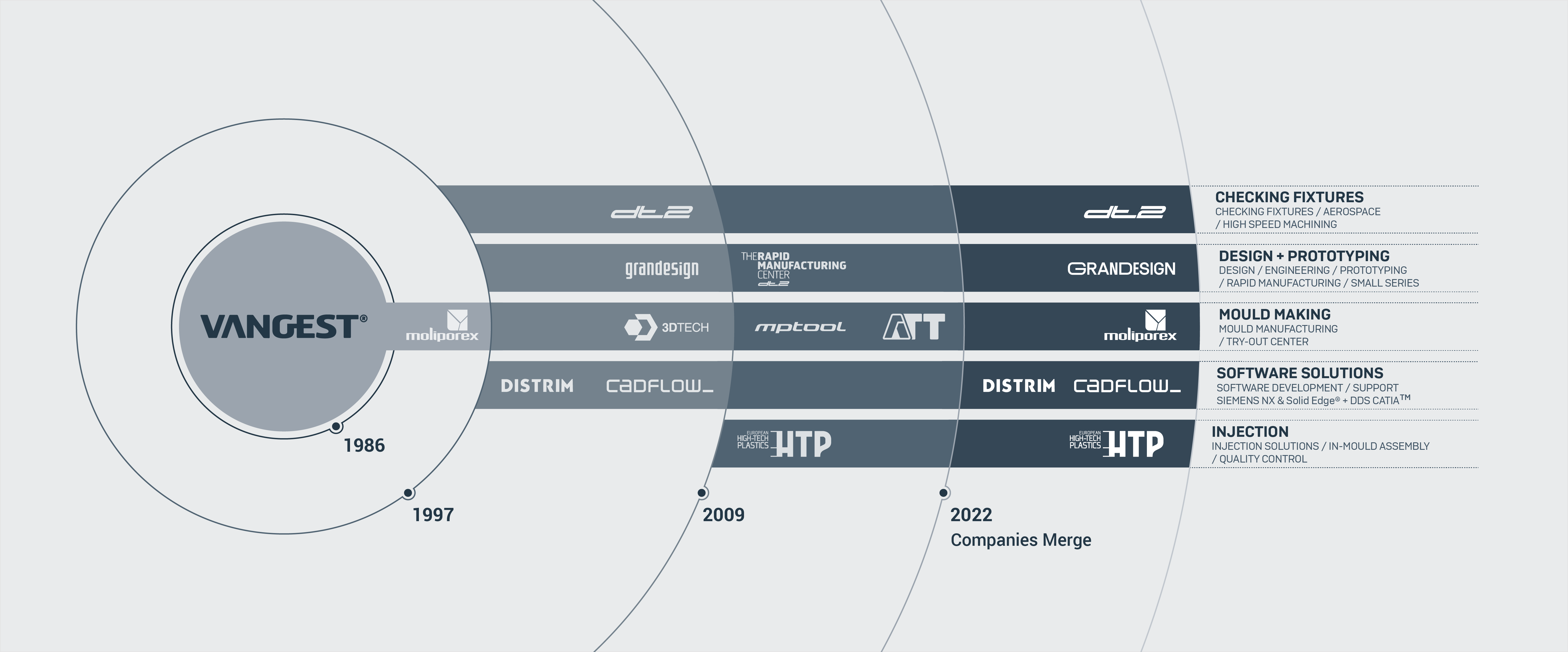

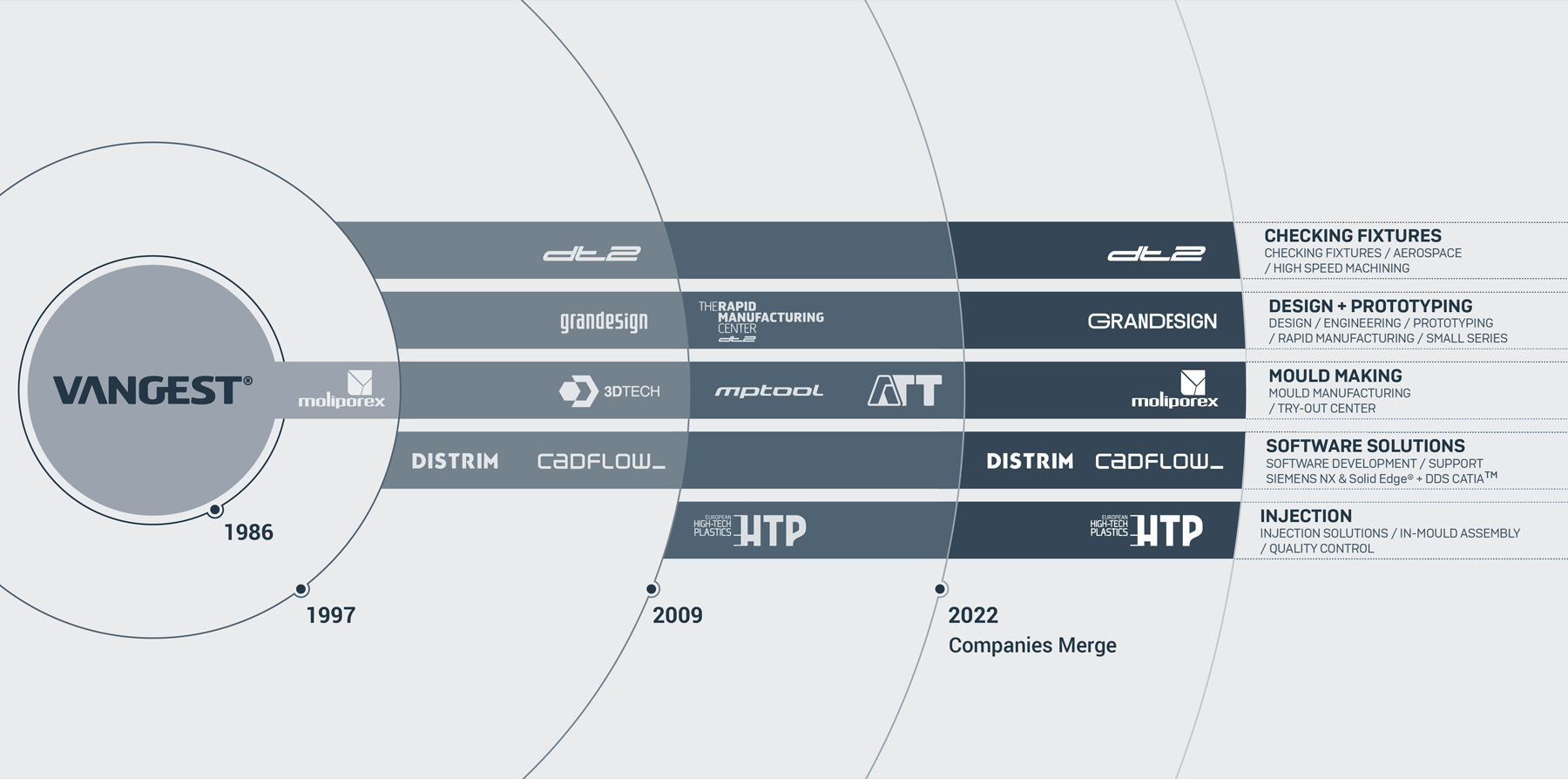

1986

A new beginning for mould making industry

In 1986, fueled by ambition and foresight, Carlos Oliveira founded MOLIPOREX in Marinha Grande. He foresaw the future demands of the mould-making industry and established the company just before Portugal gained global recognition for its high-quality moulds production. This strategic move firmly positioned MOLIPOREX as one of the leaders in this high-tech enterprise.

One year after its foundation, MOLIPOREX exported its first mould to the United States of America and has since grown consistently and sustainably.

1992

Elevating future companies with strategic PLM solutions

Carlos Oliveira and his brother Victor Oliveira, who joined him in the early 1990s, developed a strategy to create an integrated offer for the global market, based on the highest standards of management and technology. This strategy included DISTRIM, a technology and software company founded in 1992, with the aim of implementing, in the Portuguese market place, PLM solutions. This technology was considered to be one of the most revolutionary in the mould making industry.

1997

VANGEST industrial complex: starting integrated services solutions in a customer-centric approach

Always with a visionary mindset, Carlos Oliveira and his brother Victor Oliveira foresaw the demand for integrated services in the product development field. In the mid-1990s, they emerged as industry drivers by establishing a multi-service platform. The expertise gained by then and the consistent investment in cutting-edge technologies enabled them to assume a pioneering role in the market, primarily focusing on product development and workflows. These years marked a period of consolidation for the companies, culminating in the birth of the VANGEST Group. With the companies situated within the same industrial complex, the provision of integrated services was streamlined, further reinforcing the added value for clients.

GRANDESIGN was created to transform ideas into new products through an integrated process of design, engineering and rapid prototyping.

DT2 has become a global reference on checking fixtures, engineering and manufacturing.

CADFLOW was established as an information technology company dedicated to supplying PLM solutions to the Portuguese market.

3DTECH was founded to provide high-performance solutions for mould manufacturing.

2009

Expanding Integration: production capacity increases and The Rapid Manufacturing Centre emerges

Analysing and recognizing the market demands, VANGEST has expanded with the establishment of new companies equipped with advanced technologies, to increase production capacity and continue to offer clients high-value integrated solutions, with competitive delivery times and prices. With MPTOOL, which specializes in large moulds, manufacturing capacity has increased to 35 tonnes. The growing need for rapid prototyping and small series production led to the creation of the Rapid Manufacturing Centre.

2012

More cutting-edge technology and more specialization: the Thermoplastic Injection Unit is born

Investment in state-of-the-art technologies to consistently deliver optimal solutions remains a priority. This commitment led to the establishment of European High-Tech Plastics (EHTP), a thermoplastic injection unit. Exclusively utilizing all-electric injection machines, it specializes in high-quality production of complex technical components for the food & beverage, medical, automotive, and electro-electronic industries.

2015

Next step: small moulds and high precision with state-of-art equipment

ATT – Advanced Tool Technology company was established to focus on high-precision technical moulds, employing sophisticated technologies that include Advanced Flexible Machining systems with robots integrated.

2020

Industry 4.0: innovation and performance converging in excellence

Investment in advanced technologies continues to strengthen, and autonomous manufacturing capacity expands with the Digital Factory – a state-of-the-art facility that takes sustainability and energy efficiency into account. The factory is temperature-controlled, has advanced insulation, a solar panel roof, and a digital energy management system to optimize the operation of our machines as efficiently as possible, including the flexible manufacturing systems.

2022

Companies merger: Resources optimization

As a result of continuous optimization in our operations, the old legal entities of MPTOOL, 3DTECH, and ATT merged into a single legal entity – MOLIPOREX. This allowed us to simplify our administrative processes and create further synergies within our Mould Business Unit. The key specialization of the factories remains untouched. Our mission is to continue offering engineering services and high-quality moulds, from ultra-precision to large. This was also the path followed by Grandesign and DT2 RMC, which merged into a single entity: Grandesign. This merger has brought together and further enhanced the New Product Design, Prototyping & Small Series services.

2022

Companies merger: Resources optimization

As a result of continuous optimization in our operations, the old legal entities of MPTOOL, 3DTECH, and ATT merged into a single legal entity – MOLIPOREX. This allowed us to simplify our administrative processes and create further synergies within our Mould Business Unit. The key specialization of the factories remains untouched. Our mission is to continue offering engineering services and high-quality moulds, from ultra-precision to large. This was also the path followed by Grandesign and DT2 RMC, which merged into a single entity: Grandesign. This merger has brought together and further enhanced the New Product Design, Prototyping & Small Series services.